OEM/ODM China Earthing System Inspection Pit - Exothermic Welding Mould Making – ShiBang

OEM/ODM China Earthing System Inspection Pit - Exothermic Welding Mould Making – ShiBang Detail:

- Place of Origin:

-

Zhejiang, China (Mainland)

- Brand Name:

-

SHIBANG

- Model Number:

-

MJ-J034

- Shaping Mode:

-

Preform Mould

- Product Material:

-

Graphite

- Product:

-

Welding Mould Making

- Item:

-

Welding Mould Making

- Material:

-

Graphite

- Service times:

-

50-100 times

- Certification:

-

Assessed by CEPRI

- Supply Ability:

- 10000 Set/Sets per Month

- Packaging Details

- Carton+pallet for Welding Mould Making

- Port

- NINGBO/SHANGHAI

| Item | Welding Mould Making |

| Material | Graphite, Ensure the high temperature resistance |

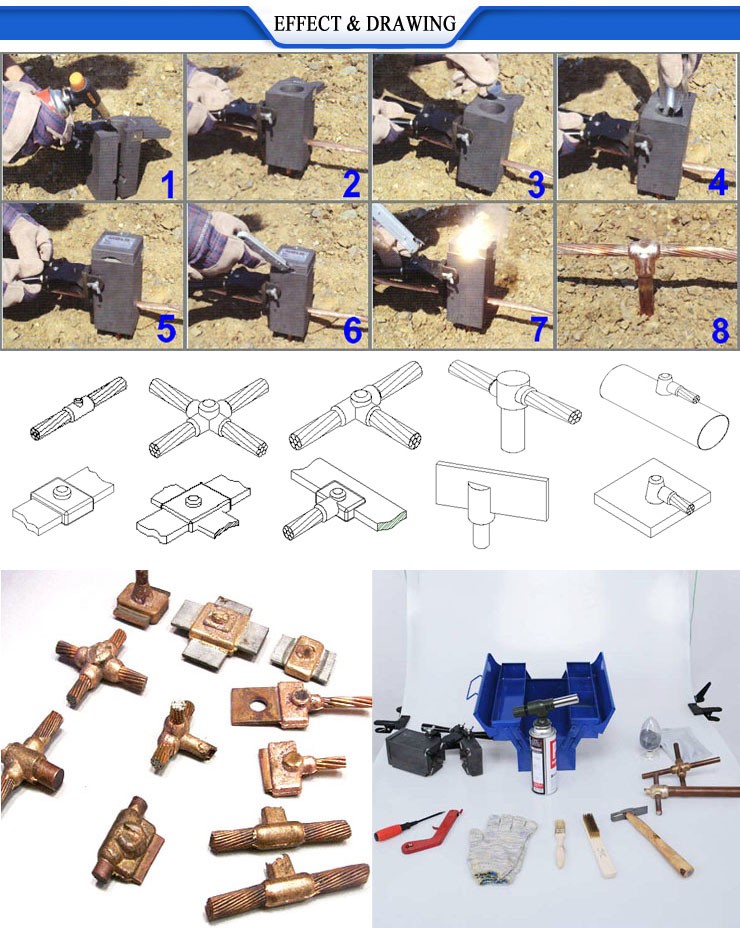

| System Concluding | Graphite Mold, Flint Gun, Heat Resistant Glove, Fastening Clamp, Metal Disc, Powder, Steel Brush, Banister Brush, etc. |

| Characters | Cost-effective, no extra power required makes it portable |

| Service Life | Around 50 Times |

| Operation | Easy and no special skill required |

| Test | Authorizated by professional third party |

|

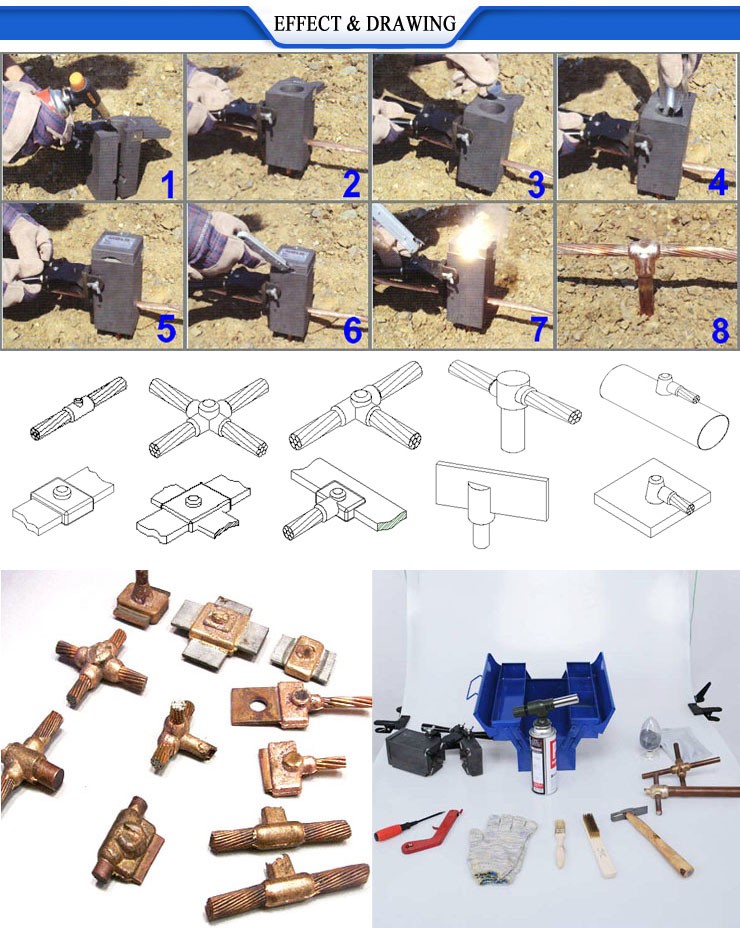

Welding Mould Making is a simple, effective , quality welding method ,which weld the parts to desired size and type in graphite mould cave with overheat melting .Currently ,the Exothermic Welding replaced mechanical connection widely. As professional graphite mould supplier, our factory offer competitive graphite mould.

Graphite Mould :The mould is made of quality graphite body to obtain the perfect seal and lasting performance .The life of our mould can be 80-100 joints ,which is more lasting than other competitor’s

Exothermic welding powder: We mix the powder comply with your conductor’s material and size with reasonable ratio ,so the joint is more strong and more lasting.

Tool box: We offer the full sets tools to meet your demand ,including ignition gun ,brush ,wrench ,screwdriver and glove . It is a package box to meet your whole demand. |

Notes:

1. Avoid contacting of hot molten metals with water, oil, grease, etc. It may cause excessive

spatter and burns

2. Do not uses in flammable vapors or dust, a fire or explosion may happen

3. Void fire, mould must be stored in dry, well-ventilated area, away from open flame and excessive heat

4. Avoid looking directly at the light of the reaction. It may irritate your eyes

5. Wear safety glasses and leather gloves to use the mould

| 1. | IQC(Incoming Check) |

| 2. | IPQC(Process Quality Control |

| 3. | First Piece Quality Control |

| 4. | Mass Products Quality Control |

| 5. | OQC(Outgoing Quality Control) |

| 6. | FQC(Final Quality Check) |

|

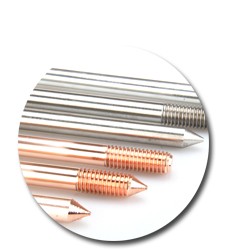

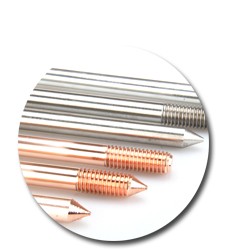

XINCHANG SHIBANG NEW MATERIAL CO., LTD is one of the first-classed manufactures which integrated research and development and sales of lighting protection facility. SHIBANG is concentrating on producing lighting rods, nonmagnetic earth rod, copper clad steel ground rod, graphite ground module, chemical electrolytic ground pole, copper bonded steel tape, copper bonded stranded wire, copper busbar, all kinds of earthing clamps, exothermic welding mold and powder etc.

SHIBANG is located in Xinchang city, Zhejiang province, which is famous for tourism, north to Shanghai and east to Ningbo makes the transportation very convenient. With the complete and scientific management system, company has got approvals from worldwide clients on products quality and reputation. Welcome to vist SHIBANG, we are waiting for cooperation with your esteemed company from all over the world. |

| 1. | Providing Professional Advises & Operation |

| 2. | Customer Service Online with 24 Hours |

| 3. | Full Inspection On All The Products Before Shipement |

| 4. | Free Logo Embossing |

| 5. | Shipping &Price Term: EXW;FOB;CIF;DDU |

| 6. | OEM & ODM Are all Available |

| 1. | Professional Operation Experience |

| 2. | The Sizes All Can Be Customised |

| 3. | Sample For Your Reference Available |

| 4. | Low MOQ, Low Price |

| 5. | Safe Packing & Prompt Delivery |

| 6. | Quality Guaranted: ISO9001:2008, UL, All Kinds of Test |

Product detail pictures:

Related Product Guide:

The customer satisfaction is our primary goal. We uphold a consistent level of professionalism, quality, credibility and service for OEM/ODM China Earthing System Inspection Pit - Exothermic Welding Mould Making – ShiBang, The product will supply to all over the world, such as: Mexico, Florence, Greece, Although continuous opportunity, we have now now developed serious a friendly relationship with many oversea merchants, such as ones through Virginia. We securely assume that the merchandise regarding t shirt printer machine is often good through a great number of having its good quality and also cost.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.